Nanotextures solve a historic problem

Nanotexturing that prevents scale forming on the inside of pipes can reduce plant maintenance costs significantly

MIT has developed a technology to optimise the conversion of CO₂ into organic compounds, adding to its potential applications in areas such as food protein production and sustainable concrete manufacturing.

The fight against climate change involves multiple strategies. While the energy transition and commitment to renewables are key, other approaches, such as the circular economy, are set to play an essential role. Imagine a factory that generates CO₂, captures it, and then converts it into a material that reinforces concrete structures. By using carbon dioxide as a raw material, we could turn it into an ally in the global effort to reduce emissions. Carbon sequestration technologies have been explored in many contexts. This article highlights how MIT is advancing the potential uses of CO₂ after it has been captured.

For carbon dioxide to become a viable resource, both the sequestration process and its conversion into useful compounds need to achieve high levels of efficiency. MIT has recently introduced a breakthrough technology designed to improve these processes.

The innovation involves an electrode design that enhances the electrochemical reactions used to convert carbon dioxide (CO₂) into chemicals like ethylene and other organic compounds. The electrode system features thin copper wires woven through a conductive membrane, enabling a more direct interaction with the catalyst. This design increases the speed and selectivity of chemical reactions.

To validate this system, researchers conducted controlled laboratory tests that demonstrated high conversion rates of CO₂ with minimal energy consumption. Additionally, the modular design of the electrode allows for scalability in industrial operations without compromising efficiency.

Advances in carbon sequestration systems and catalysts, such as the technology developed by MIT, have paved the way for innovative uses of carbon dioxide. Below are five promising applications.

Concrete production is an energy-intensive process and a major source of greenhouse gas emissions. However, injecting liquid CO₂ into the concrete mix initiates a mineralisation process that sequesters the gas within buildings and infrastructure, reducing the material's overall carbon footprint.

Biochemical processes can use CO₂ to produce cellulose for textiles. Enzymes are employed to generate cellulose pulp, which is then transformed into fibres. The resulting material, known as lyocell, is commonly used in clothing and home textiles such as bed linen.

Long-duration space missions, such as potential Mars colonisation, will require food production on-site. One solution involves using microbes that feed on hydrogen and CO₂ to manufacture synthetic proteins. The dry residue from this process is nearly pure protein, making it a viable option for both space and Earth-based applications, as explained in this article.

Carbon dioxide can also be utilised in the production of sodium bicarbonate, a versatile compound used in baking and antacids. Some chemical companies have already developed processes that combine CO₂ and sodium hydroxide to synthesise this product.

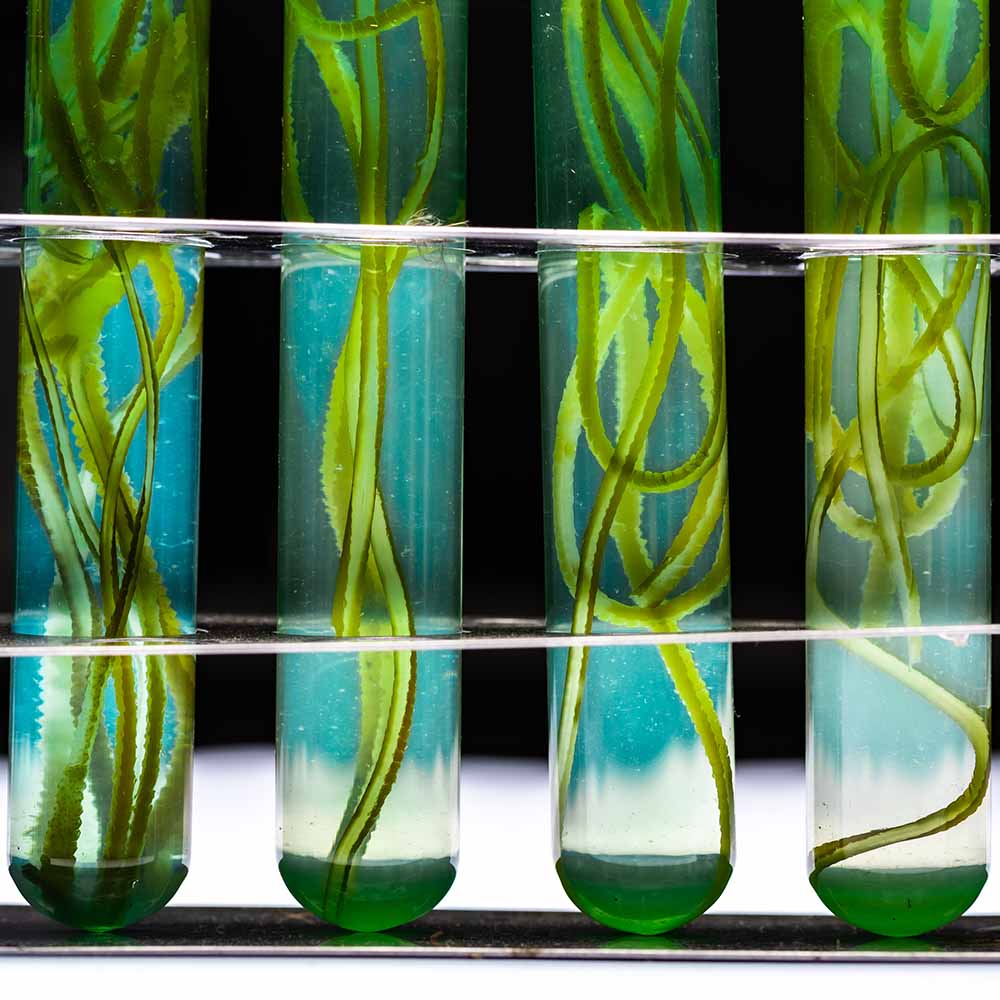

Using carbon dioxide to cultivate algae is another promising application. Algae are expected to become a cornerstone raw material in the coming decades, especially in the food and biofuel sectors. A company in Cádiz (Spain), for example, grows algae near factories and power plants, utilising CO₂ emissions to produce materials for compost and cosmetics.

Although these solutions present promising opportunities to reuse CO₂, the most effective strategy to combat global warming remains preventing emissions at their source. Renewable energy sources, such as wind, solar, and wave power, continue to represent the safest and most reliable path in the fight against climate change.

Source:

All fields are mandatory.

Read the most discussed articles

{{CommentsCount}} Comments

Currently no one has commented on the news.

Be the first to leave a comment.

{{firstLevelComment.Name}}

{{firstLevelComment.DaysAgo}} days ago

{{firstLevelComment.Text}}

Answer{{secondLevelComment.Name}}

{{secondLevelComment.DaysAgo}} days ago

{{secondLevelComment.Text}}