-

The White Tower: Setting New Heights in 3D-Printed Construction

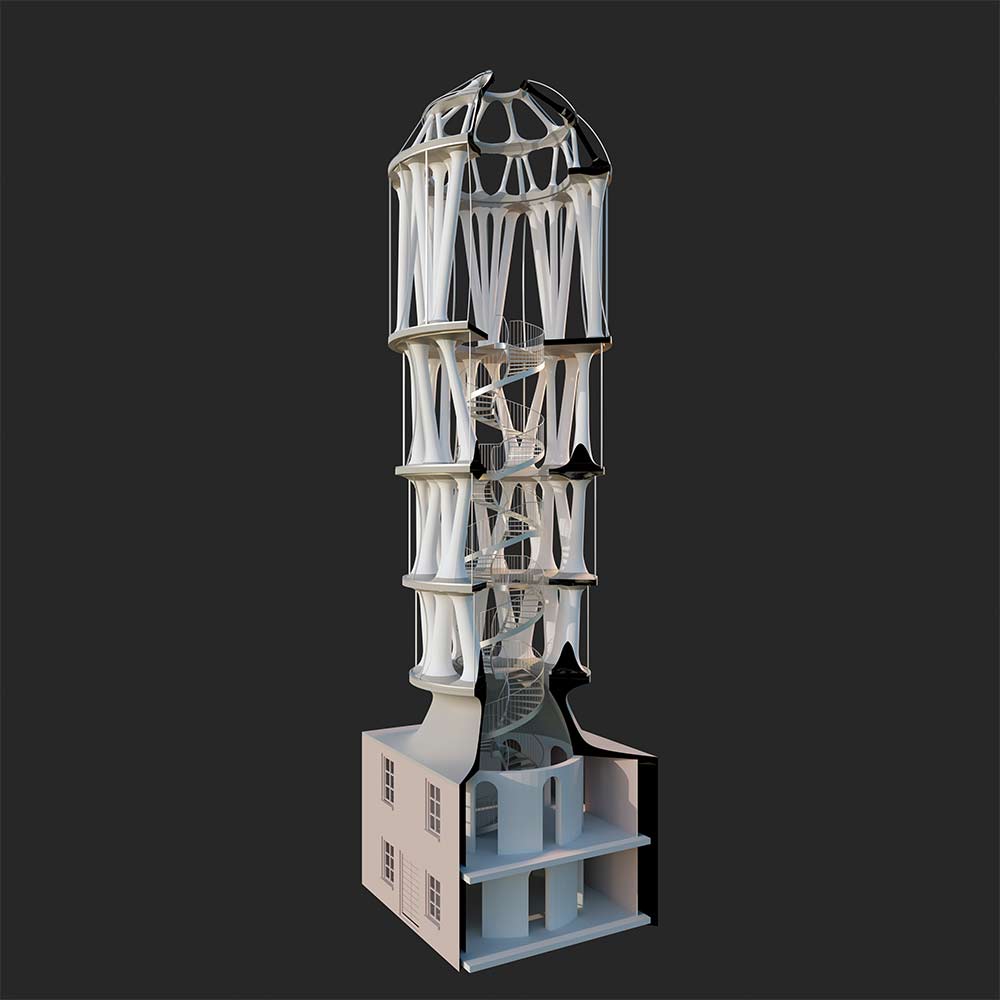

This building from the ETH Zurich Technology Institute in Switzerland is set to become the tallest structure of its kind worldwide.

3D printing in construction is revolutionizing the industry, offering a faster, more affordable, sustainable, and creative method for creating living spaces. This technology is altering construction methodologies and expanding architectural design possibilities, turning previously unfeasible projects into reality. The White Tower, or Tor Alva, is an initiative by the ETH Zurich that exemplifies 3D printing's potential in construction.

The White Tower overlooking the Alps

This thirty-meter-high building crafted through 3D printing with concrete extrusion is envisioned as a space for art installations and musical and theatrical performances. Its innovative design draws inspiration from the baroque builders of Canton Graubünden in Switzerland while embracing the possibilities offered by computational design and digital fabrication to revamp traditional building systems.

With a printing process that reduces concrete consumption by half and eliminates the need for formwork, the tower promotes a modular and sustainable construction method for the structural elements, which can be disassembled and rebuilt in another location. Designed to act as a beacon for travelers, the White Tower will be positioned along the Juliers Pass in the Alps, near the remains of an ancient Roman sanctuary. The structure will feature one hundred and two columns 3D printed with white concrete, supporting different levels connected by a spiral staircase. The top floor is designed to house an auditorium with seating for fifty people.

The construction process of the tower is anticipated to be completed in less than 900 hours, demonstrating the significant potential of 3D printing technologies in construction to streamline project timelines. And that is not the only advantage of this construction technique.

Advantages of 3D printing in the construction industry

3D printing in the construction sector is revolutionizing how structures are conceptualized, designed, and built. This technology offers several significant benefits that make it particularly attractive for various projects.

- Accelerated construction times: As noted above, the ability to 3D print components and structures continuously allows projects to be completed in a much shorter timeframe compared to traditional construction methods.

- Design flexibility: 3D printing in construction offers unprecedented design freedom, allowing the creation of shapes and structures that would be difficult or impossible to realize with conventional techniques.

- Sustainability: This technology promotes sustainable construction by minimizing material waste and enabling the use of more environmentally friendly materials. The precision of 3D printing in construction ensures that only the exact amount of material needed for each project is used.

- Customization: Allows mass customization of projects at a relatively low cost. Each element can be designed and manufactured to meet specific needs without significantly increasing production costs since no molds or formwork are required.

- Improved safety: The automation of the construction process through 3D printing reduces the exposure of workers to hazardous working conditions, minimizing the risk of accidents in the workplace.

- Cost reduction: 3D printing can significantly reduce construction costs by reducing the amount of wasted materials and optimizing the use of resources. In addition, the automation of the construction process reduces the need for labor, which also contributes to cost savings. In this video, you can learn about two techniques that allow to achieve these results:

3D printing methods in the construction industry

There are various 3D printing techniques currently under research and development, each with specific applications and advantages depending on the project and its location.

- Material extrusion: Deposits materials layer by layer, commonly concrete or plastic, following a digital design. This is the additive manufacturing technique being used in the construction process of the White Tower, where a robot deposits layers as thin as five millimeters.

- Binder jet printing: Uses a liquid binder sprayed onto a powdered material, layer by layer, to form a solid object.

- Stereolithography (SLA) for construction: Creates objects by solidifying a liquid resin with ultraviolet light, layer by layer.

- Selective laser sintering (SLS) for construction: Uses a laser to melt and solidify a material powder, building the desired object layer by layer.

- Laser powder bed fusion (LPBF) or selective laser melting (SLM) for metals: Similar to SLS, but focused on metals, it melts metal powders with lasers to form complex structures.

Of all these 3D printing methods, the most common is material extrusion, especially with the use of concrete, due to its versatility, cost-effectiveness and the ability to build large-scale structures. In addition, this technique allows for a wide range of applications in the construction sector, from small components to entire buildings.

Interested in exploring further applications of 3D printing in construction? Dive into this insightful article to see how art and architecture merge beautifully in the creation of an extraordinary piece of 3D-printed street furniture.

Source:

Imágenes:

- ETH Zurich

Write your comment

All fields are mandatory.

Thank you for your comment

More about Construction

Featured topics

Read the most discussed articles

{{CommentsCount}} Comments

Currently no one has commented on the news.

Be the first to leave a comment.

{{firstLevelComment.Name}}

{{firstLevelComment.DaysAgo}} days ago

{{firstLevelComment.Text}}

Answer{{secondLevelComment.Name}}

{{secondLevelComment.DaysAgo}} days ago

{{secondLevelComment.Text}}